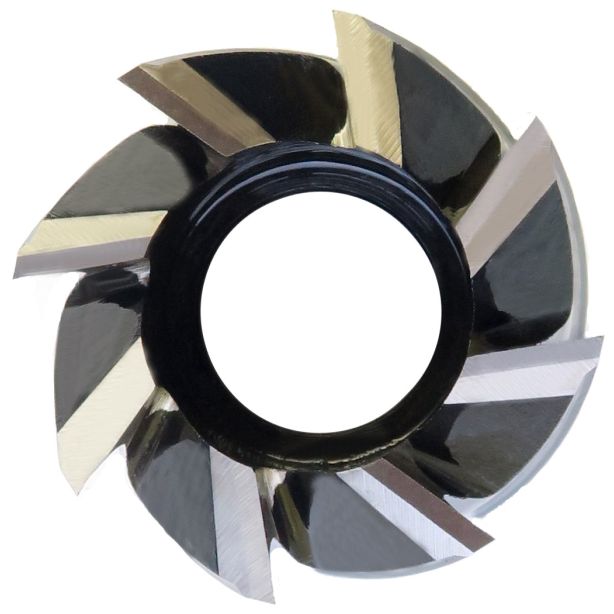

510N Shell End Mills

In stock

SKU

510N

M2 High Speed Steel Right Hand Cutting BSS 122 part 1 (1953)

Right Hand Spiral Teeth. With front recess and rear driving slot (BSS122 or DIN 138)

Metric sizes also have a keyed bore DIN1880 Type N

Cutters for general-purpose shell end milling in most ferrous and some non-ferrous materials. The fractional

sizes shown below are those of the ‘new’ standard (issued in 1953). Tools to an older standard from 1926,

which are to different dimensions and fit different arbors, can still be made to special order.

Details

* Number of teeth (Z) in cutters may not cover all the current stocks, and cutters with small differences in the number of teeth to those shown above may be supplied.

The following similar tools may be supplied to special order: the quantity ordered determines the unit price:

Shell End Mills with Left Hand Spiral and Left Hand Cutting Teeth

Shell End Mills with Chamfered front corners Cutters to customer drawings

Shell End Mills with radiused front corners

Cutters in cobalt or PM-material

Special geometry cutters optimised for cutting particular materials. These can include the recommendations for light alloys, with high front rakes and coarser

tooth pitches (DIN1880 Type W) or with closer pitch and reduced cutting rakes for hard, shortchipping materials (DIN1880 Type H)

——————————————

HSS “Face Mills”, which are similar to the above, but with a raised boss and horizontal driving slot (to an even older standard) in the BS series, and to DIN841 in

the metric series, may still be called for, and can also be produced to special order.